Understanding Sump Pump Check Valves: Essential Maintenance Tips for Optimal Flood Protection

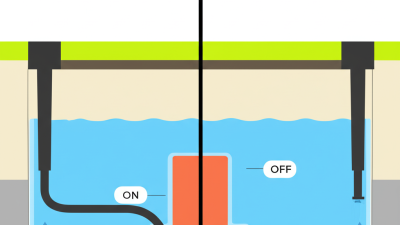

When it comes to safeguarding your home from flooding, understanding the role of a sump pump check valve is crucial. A sump pump check valve serves as a vital component in preventing backflow and ensuring that the water pumped out of your basement or crawl space does not return. This essential mechanism can make the difference between a dry, protected home and one that faces costly water damage.

To optimize the performance of your sump pump and enhance your flood protection strategy, it is important to recognize the maintenance tips associated with the sump pump check valve. In this guide, we will explore the best practices for inspecting, cleaning, and ultimately prolonging the life of this critical device, ensuring that your home remains secure against the threat of water intrusion.

Understanding the Importance of Sump Pump Check Valves in Flood Prevention

Sump pump check valves play a critical role in flood prevention by ensuring that water is effectively pumped away from vulnerable areas and does not flow back into the sump basin. According to a report from the National Association of Home Builders, nearly 60% of homeowners experience some form of water damage in their homes, and malfunctioning sump pumps are a common cause. By installing a reliable check valve, homeowners can significantly reduce the risk of flooding and protect their property from expensive repairs.

To maintain optimal performance, here are some essential tips to consider. First, inspect the check valve regularly for any signs of wear or damage. A properly functioning check valve should have a tight seal, preventing backflow. If you notice leaks or gaps, it’s time to replace the valve. Second, ensure that the sump pit is clear of debris, as clogs can hinder the valve's efficiency. Regular cleaning can help maintain the system's integrity and prolong the lifespan of the pump.

Finally, consider conducting an annual maintenance check. According to the American Society of Home Inspectors, a proactive approach to sump pump maintenance can reduce the likelihood of failure during heavy rainstorms by up to 80%. Investing time in understanding and caring for your sump pump check valves can lead to efficient flood protection and peace of mind.

Key Maintenance Practices: How Often Should You Inspect Your Check Valve?

Regular inspection of your sump pump check valve is crucial for maintaining optimal flood protection in your home. These devices prevent backflow into your sump pit, and a malfunction can lead to a flooded basement. It is generally recommended to inspect your check valve at least twice a year—preferably in spring and fall. During these inspections, look for signs of wear, such as corrosion, leaks, or debris that might be obstructing the valve's function.

In addition to biannual checks, it’s important to pay attention to any indicators of failure, such as unusual noises from the sump pump or water accumulating around the sump pit. If you notice any irregularities, it may be best to consult a professional for a more comprehensive evaluation and possible replacement of the check valve. Regular maintenance not only extends the lifespan of your sump pump system but also ensures that you are well-prepared for heavy rainfalls or flooding events.

Critical Signs Your Sump Pump Check Valve Needs Immediate Attention

Sump pump check valves are crucial components in preventing flood damage by ensuring that water flows in one direction — away from your home. However, over time, these valves can wear down or become obstructed, necessitating immediate attention. One critical sign that your sump pump check valve needs maintenance is the presence of water pooling near the pump's base. If you notice water accumulating despite your sump pump running, it may indicate that the check valve is stuck or malfunctioning, allowing water to flow back into the pit.

Another warning sign is a noticeable increase in the frequency of your sump pump cycling. If the pump seems to activate more often than usual, it could be struggling to push out water effectively due to a failing check valve. Additionally, listen for unusual sounds, such as gurgling or rattling, which may suggest debris is blocking the valve or that it’s failing to seal properly.

Regularly inspecting these components and addressing any of these signs promptly is vital to ensure your sump pump operates efficiently, providing optimal flood protection for your home.

Impact of a Malfunctioning Check Valve: Statistics on Flood Damage Costs

A malfunctioning check valve can have significant financial implications, especially in flood-prone areas. Statistics indicate that flood damage costs have reached alarming levels, with even minor flooding incidents leading to thousands of dollars in repairs. Poorly maintained sump pump systems, particularly those with ineffective or broken check valves, can exacerbate these issues by allowing backflow of water, ultimately leading to basement flooding. In some cases, homeowners have reported losses exceeding tens of thousands in damages due solely to check valve failures.

Recent flooding events, like the severe incidents in Southwest Detroit, highlight the broader risks associated with inadequate flood protection systems. As climate change continues to intensify weather patterns and increase the frequency of flooding, the urgency for effective maintenance and repair of sump pump systems cannot be overstated. It's critical for homeowners to understand the importance of a functioning check valve to mitigate flood-related costs and ensure optimal protection for their properties. Regular inspections and maintenance of these systems are essential to avert potential disasters that could lead to devastating financial repercussions.

Understanding Sump Pump Check Valves: Essential Maintenance Tips for Optimal Flood Protection

| Parameter | Value |

|---|---|

| Average Lifespan of Check Valve | 5-7 years |

| Percentage of Homeowners with Check Valve Issues | 30% |

| Average Flood Damage Cost (Per Incident) | $25,000 |

| Emergency Repair Costs for Sump Pumps | $400-$1,200 |

| Maintenance Frequency Recommendation | 1-2 times a year |

| Common Check Valve Failure Causes | Debris, Wear and Tear, Improper Installation |

Best Materials for Sump Pump Check Valves: Durability and Performance Insights

When selecting a sump pump check valve, the materials used play a critical role in both durability and performance. High-quality options often include PVC, brass, and stainless steel. PVC is popular for its lightweight nature and resistance to corrosion, making it an economical choice for many residential applications. However, while PVC is effective, it may not be as durable under extreme conditions compared to metals.

Brass and stainless steel check valves offer enhanced longevity and strength, making them suitable for harsher environments. Brass is known for its high resistance to rust and can withstand a broader range of temperatures, which is beneficial for sump pumps in variable climates. On the other hand, stainless steel provides exceptional durability, especially in systems that handle abrasive materials or harsh chemicals. Investing in valves made from these materials can greatly improve the overall reliability of your sump pump, reducing the risk of failure during critical flood situations.